The quality of rinse water used in the automotive industry is extremely important during the degreasing of body parts before painting and during surface treatment processes. In order to keep water consumption to a minimum and to prevent the heavy metals from entering the wastewater, water recycling should be accomplished by selective ion exchange or membrane filtration.

The proper water quality is also essential in many other areas of the industry, such as water used for humidifiers, cooling water, or boiler water.

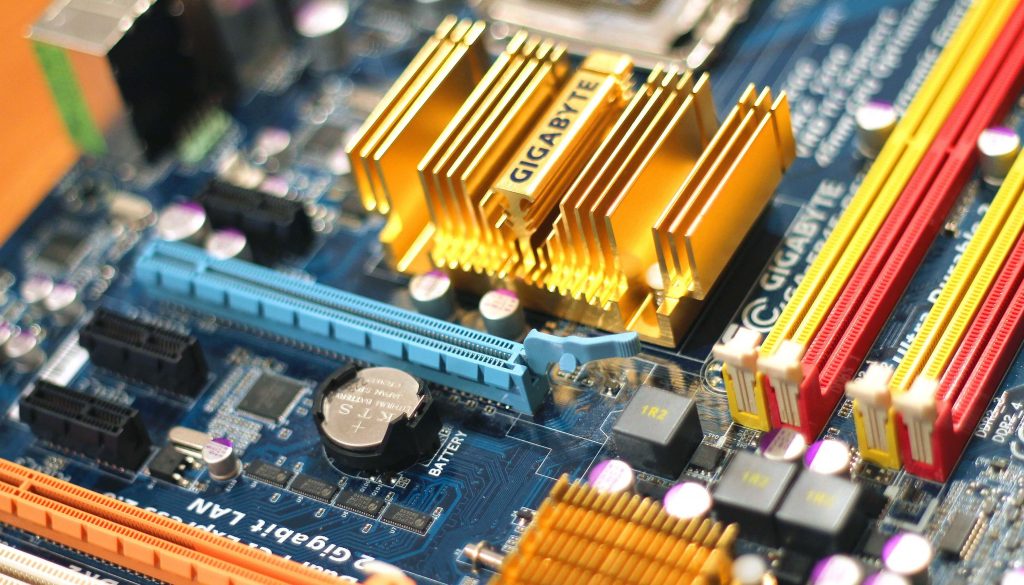

The use of high purity water is essential in the manufacturing of electronic components. The theoretically achievable lowest level of water conductivity is 0.055 micro Siemens per cm (µS/cm), whichcan only be achieved with efficient water treatment.

We provide our partners with solution that not only adapts to the individual needs of consumers, but also satisfies the strict requirements of the business.

Painted works are now replacing the previously widespread and frequently used galvanization. During this time other pretreatment processes have also developed, such as phosphating and chromating, which provide corrosion protection. However, both processes must meet strict requirements for process water preparation.

To realize surface treatment projects, our company has a wide range of ion exchange and membrane filter equipments. Additionally, we recommend an equipment for the removal of metals in wastewater, whichcan be reduced to less than 0.1 mg/l per metal.

Water treatment contributes to the creation of perfect surfaces and ensures a long service life for the work pieces.

Proper quality of boiler water, rinsing water, cooling water, water used for humidifiers and water used for cutting oil emulsion additives is essential for companies engaged in mechanical engineering. Additionally the use of desalinated water is recommended for the use of cooling and lubricating fluids.

There are numerous benefits when using desalinated water. It provides better cooling and lubrication, extends tool-lifetime, minimizes the growth of microorganisms and corrosion, and additionally it reducesenviromental costs too.

Our company distributes and manufactures both ion exchange and reverse osmosis (RO) equipments with outstanding expertise to meet the requirements of theseindustries.

For the pharmaceutical industry, the process water must be of high purity and must comply with the stated requirements for water treatment equipment devices found in the Pharmacopoeia.

In the pharmaceutical industry, water plays an important role in the products, in the manufacturing process, and it isalso a part of the purification process. Public water is therefore unsuitable, as it contains salts, organic matter, microorganisms and mechanical particles, which can be removedonly by membrane filtration. UV disinfection units as well as sterile filters can be installed as a special precaution against microorganisms.

Not only the equipment needed to produce process water for the industry, but also the piping systems for the accessories must be adequate for the requirements. Proper design and construction is crucial for the quality of the final product. The choice of materials reflects the purpose of the application, which is why our company offers a range of pipe systems made of standard materials such as: PVC, PP-N, PVDF, AISI 316L stainless steel. Wherever possible, our company adapts the materials according to the customer’s requirements.

After the completion of the water treatment equipment, we ensure trouble-free operation with an inspection program and complete product documentation, as proper water treatment contributes to maintaining the optimal quality and appearance of the product.

The textile industry needs different quality of water when handling textiles.

Rinse water also used in pre-treatment, painting, printing and generally in textile treatments. During pre-treatment, materials that are added to textiles during manufacturing processes are washed out. Softened water is required during painting and printing of textiles, excess materials are also washed out at the end of the process.

However, another important goal of water treatment is to minimize environmental impacts, such as the use of chemicals, harmful substances, and the amount of discharged wastewater.

The chemical industry is a comprehensive group that is inextricably linked to many other industries. From the production of medicines, through cleaning agents, soaps, varnishes to pesticides and chemical raw materials, water treatment is needed everywhere.

In most cases, water quality is inadequate because inorganic salinity causes disturbance, which degrades the quality of the products and processes, so proper water treatment is essential.

The constant development of new glass types and washing processes requires the removal of mechanical contaminants, keeping bacteria and organic materials in the water as low as possible.

The desalinated water can also be treated by ion change or by reverse osmosis treatment depending on theclient’s requirements. In case of significant water consumption, it is recommended to use a recycling device. Depending on the project, the equipment includes a mechanical filter, an active carbon filter and a UV equipment.

Institutions may have a wide variety of needs in the field of water treatment. For example, production of softened or desalinated water for washing machines, dishwashers, central heating systems, production of cooling water, desalinated water for steam boilers.

Our company helps to find the right solution for our customer.

9071 Gönyű, Béke u. 2.

Hungary

Phone: +36-96/544-240

E-mail: contact@euro-clear.eu

Tax number: 14009301-2-08

Company registration number: 08-09-015163

EU tax number: HU14009301

Most INGYENESEN igényelheti vízkeménység-mérő teszterünket és megtudhatja, kemény-e a víz háztartásában!